| Availability: | |

|---|---|

| Quantity: | |

ABLB100

DAWSON

Automatic Double Station Double Head Extrusion Blow Molding Machines For hanging bottle pp

DESCRIPTION

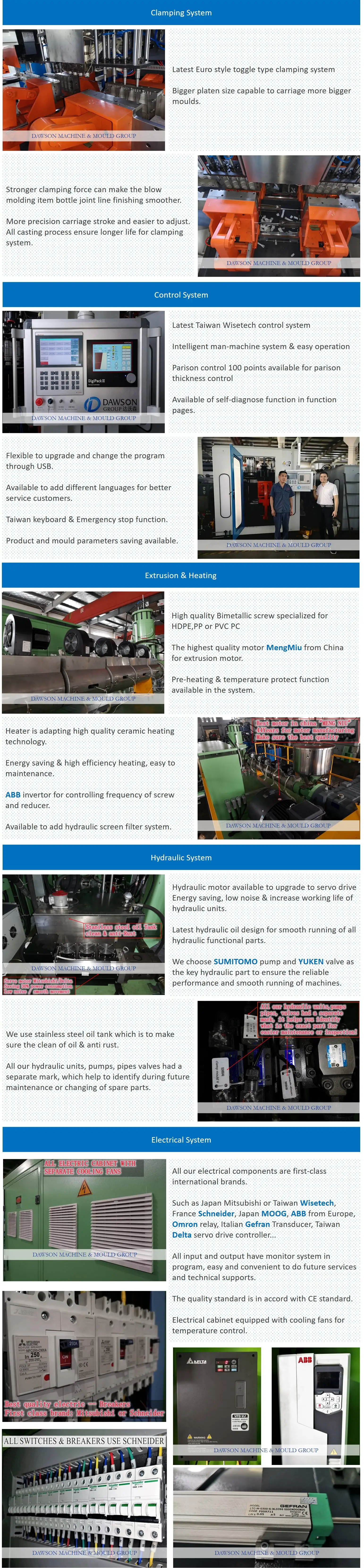

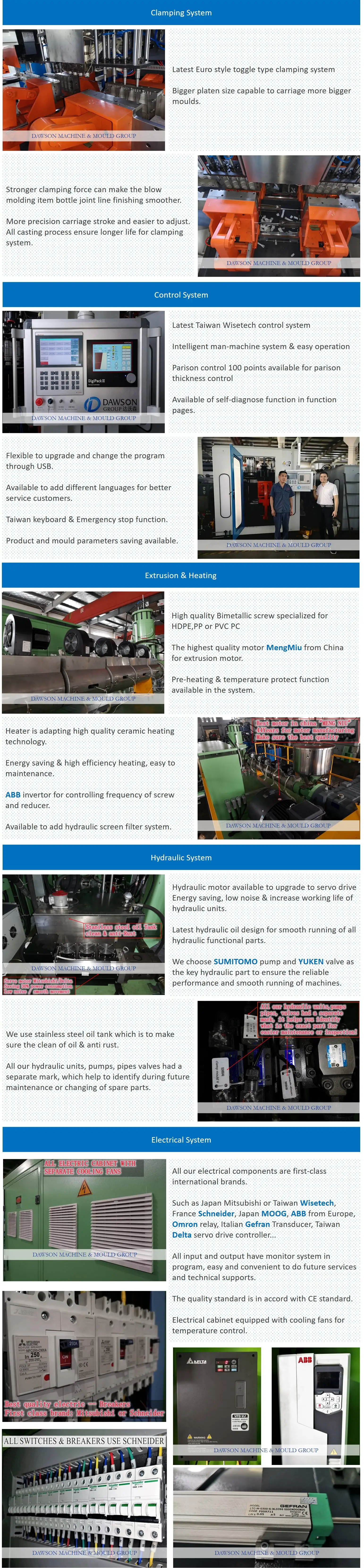

The extrusion blow molding process, which these machines execute with finesse, is a multi-step operation that combines art and science. It all begins with the plastic resin, a raw material typically sourced in pellet form. This resin is fed into the machine's hopper, from where it descends into the extruder. Inside the extruder, a powerful screw mechanism rotates, gradually pushing the resin forward while subjecting it to intense heat and pressure. As a result, the solid pellets transform into a molten, viscous mass, ready to be shaped into the desired form.

Advantage

Technical Parameter

| Name | Units | ABLB100II |

| Max.product volume | L | 0.5 |

| Screw diameter | MM | 100 |

| Screw drive power | KW | 18.5 |

| Output of HDPE | KG/H | 75 |

| Oil pump drive power | KW | 7.5 |

| Clamping force | KN | 65 |

| Max.size of mold | MM | 320×350 |

| Template size | MM | 290×320 |

| Mold stroke | MM | 150-500 |

| Max.die diameter | MM | 170 |

| Size of machine | L×W×H | 4.5×3×2.6 |

| Weight of machine | TON | 11 |

Application

|  |

Automatic Double Station Double Head Extrusion Blow Molding Machines For hanging bottle pp

DESCRIPTION

The extrusion blow molding process, which these machines execute with finesse, is a multi-step operation that combines art and science. It all begins with the plastic resin, a raw material typically sourced in pellet form. This resin is fed into the machine's hopper, from where it descends into the extruder. Inside the extruder, a powerful screw mechanism rotates, gradually pushing the resin forward while subjecting it to intense heat and pressure. As a result, the solid pellets transform into a molten, viscous mass, ready to be shaped into the desired form.

Advantage

Technical Parameter

| Name | Units | ABLB100II |

| Max.product volume | L | 0.5 |

| Screw diameter | MM | 100 |

| Screw drive power | KW | 18.5 |

| Output of HDPE | KG/H | 75 |

| Oil pump drive power | KW | 7.5 |

| Clamping force | KN | 65 |

| Max.size of mold | MM | 320×350 |

| Template size | MM | 290×320 |

| Mold stroke | MM | 150-500 |

| Max.die diameter | MM | 170 |

| Size of machine | L×W×H | 4.5×3×2.6 |

| Weight of machine | TON | 11 |

Application

|  |