| Availability: | |

|---|---|

| Quantity: | |

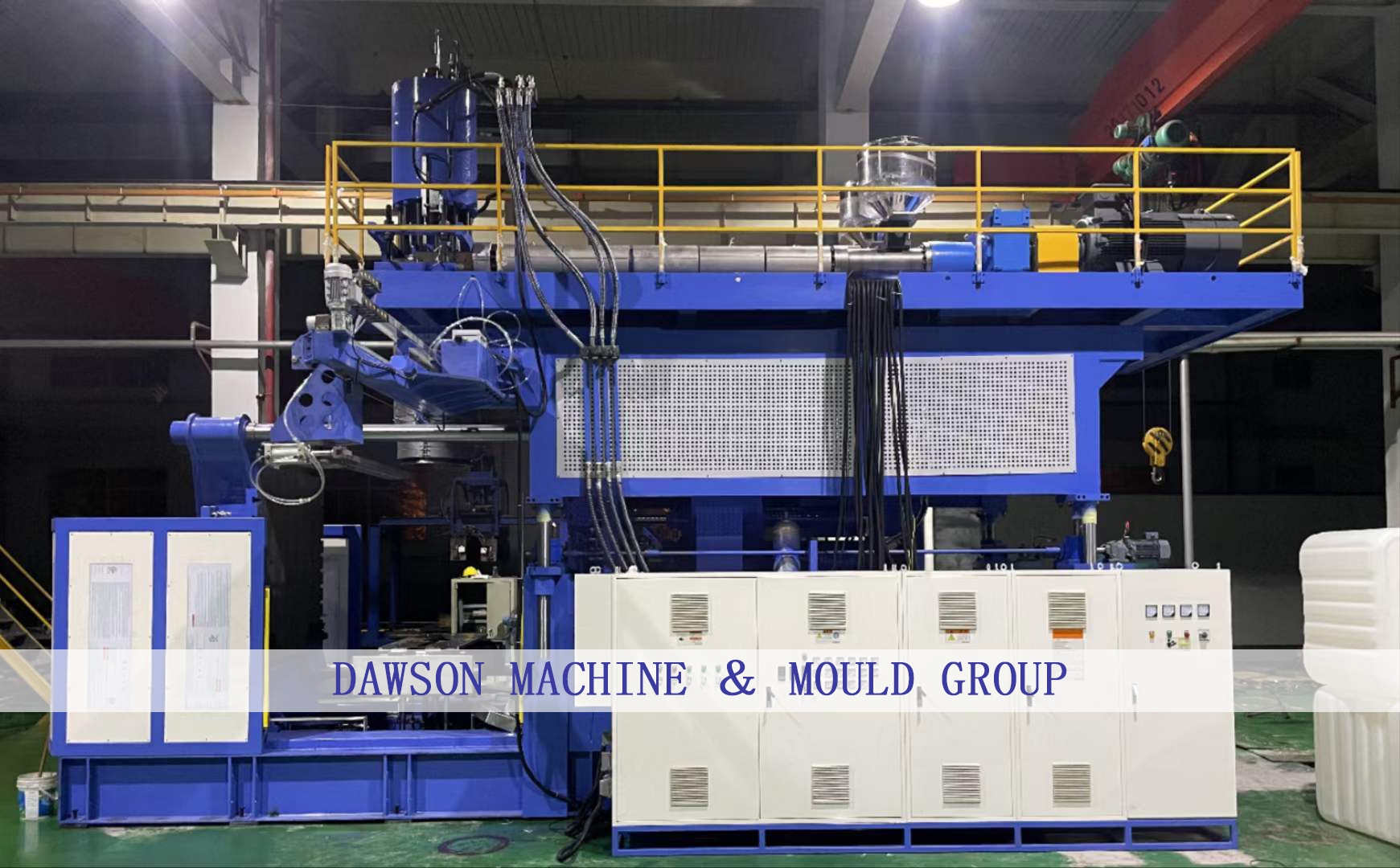

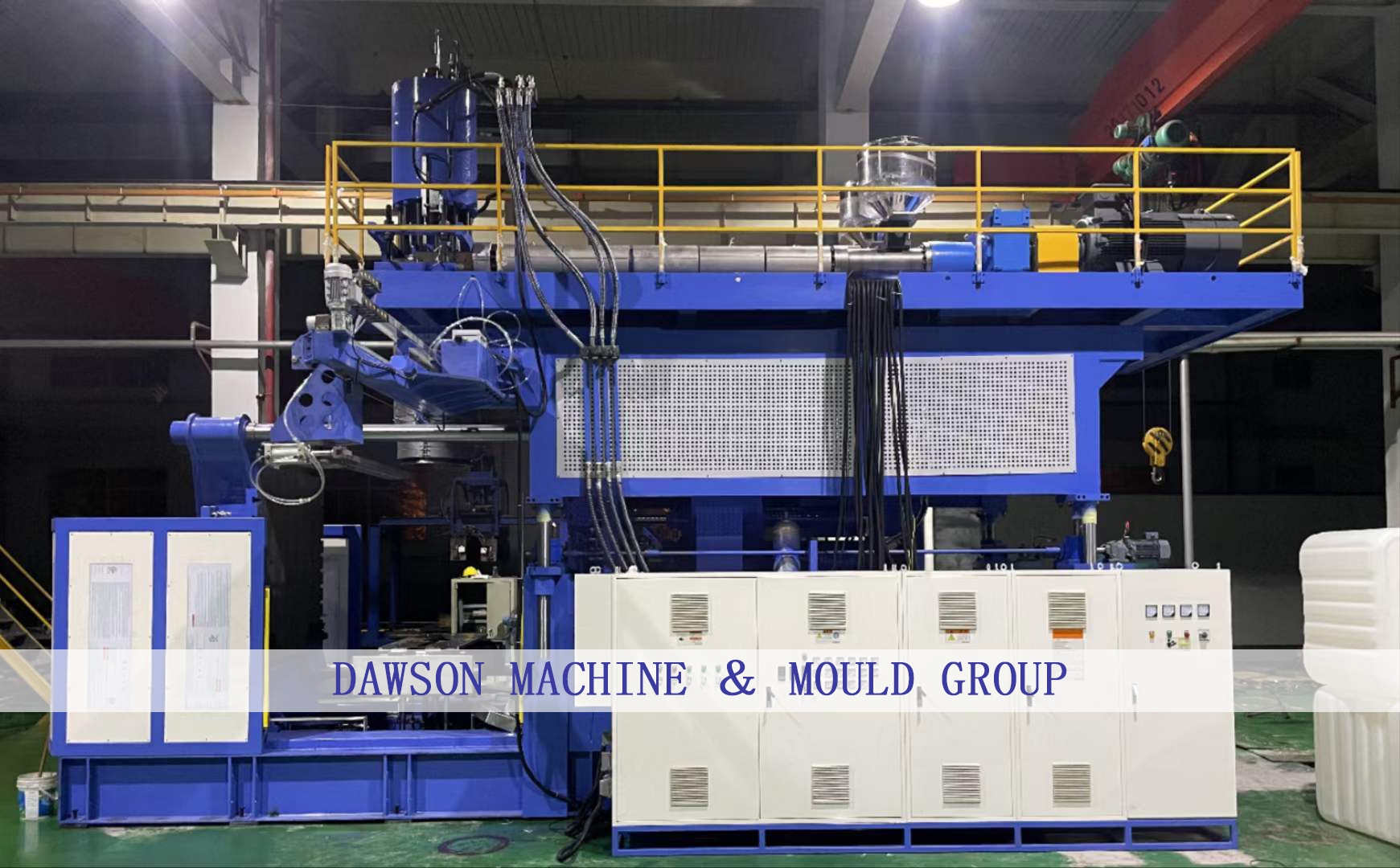

DAWSON

Here are some additional details about the IBC tank blow molding machine:

Material selection: The machine is compatible with a wide range of plastic materials, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), and polypropylene (PP). This allows manufacturers to choose the material that best suits their specific application requirements.

Technological advancements: The field of blow molding continues to evolve, and new technological advancements are being incorporated into IBC tank blow molding machines. These advancements include faster cycle times, improved energy efficiency, enhanced automation, and advanced control systems for greater precision and reliability.

Technological advancements: The field of blow molding continues to evolve, and new technological advancements are being incorporated into IBC tank blow molding machines. These advancements include faster cycle times, improved energy efficiency, enhanced automation, and advanced control systems for greater precision and reliability.

| Model | IBM35D | IBM45D | IBM65D | ||

| Item | Unit | Date | |||

| Injection system | Screw Diameter | mm | 40 | 45 | 50 |

| Max. Theoretical injection capacity | G | 176 | 260 | 314 | |

| Heating capacity | KW | 7.2 | 10 | 10 | |

| No. of heating area | Qty | 3 | 3 | 3 | |

| Clamping & blowing system | Clamping force of injection | kn | 350 | 450 | 650 |

| Clamping force of blowing | kn | 40 | 78 | 89 | |

| Opening stroke of mold platen | mm | 120 | 120 | 140 | |

| Max. Platen size (L×W) | mm | 420×340 | 560×390 | 740×390 | |

| Min. Mold thickness (H) | mm | 180 | 240 | 280 | |

| Heating capacity of mould | KW | 2.8 | 4.0 | 5.0 | |

| Product dimension range | Suitable bottle range | ml | 3-800 | 3-800 | 5-800 |

| Max. bottle height | mm | ≤180 | ≤200 | ≤200 | |

| Max. Dia. of bottle | mm | ≤80 | ≤80 | ≤80 | |

| Dry cycle | s | 4 | |||

| Hydraulic driving system | Motor power | KW | 11/15 | 18.7/22 | 17 |

| hydraulic pressure | Mpa | 14 | 14 | 14 | |

| Pneumatic system | Min. Air pressure | Mpa | ≥0.8 | 1.0 | 1.0 |

| Discharge rate of compressed air | M3/mm | ≥0.7 | ≥0.8 | ≥0.8 | |

| Cooling system | Water flowage | M3/h | 3 | 3 | 4 |

| Total rated power with mold heating | KW | 21/25 | 34/38 | 45 | |

| Machine information | Dimension | M | 3.1×1.2×2.2 | 3.5×1.4×2.3 | 4×1.28×2.35 |

| machine weight | Ton | 4.0 | 6.0 | 7.5 | |

Application

Saudi Arabia, Colombia, Panama, South Africa ...

Here are some additional details about the IBC tank blow molding machine:

Material selection: The machine is compatible with a wide range of plastic materials, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), and polypropylene (PP). This allows manufacturers to choose the material that best suits their specific application requirements.

Technological advancements: The field of blow molding continues to evolve, and new technological advancements are being incorporated into IBC tank blow molding machines. These advancements include faster cycle times, improved energy efficiency, enhanced automation, and advanced control systems for greater precision and reliability.

Technological advancements: The field of blow molding continues to evolve, and new technological advancements are being incorporated into IBC tank blow molding machines. These advancements include faster cycle times, improved energy efficiency, enhanced automation, and advanced control systems for greater precision and reliability.

| Model | IBM35D | IBM45D | IBM65D | ||

| Item | Unit | Date | |||

| Injection system | Screw Diameter | mm | 40 | 45 | 50 |

| Max. Theoretical injection capacity | G | 176 | 260 | 314 | |

| Heating capacity | KW | 7.2 | 10 | 10 | |

| No. of heating area | Qty | 3 | 3 | 3 | |

| Clamping & blowing system | Clamping force of injection | kn | 350 | 450 | 650 |

| Clamping force of blowing | kn | 40 | 78 | 89 | |

| Opening stroke of mold platen | mm | 120 | 120 | 140 | |

| Max. Platen size (L×W) | mm | 420×340 | 560×390 | 740×390 | |

| Min. Mold thickness (H) | mm | 180 | 240 | 280 | |

| Heating capacity of mould | KW | 2.8 | 4.0 | 5.0 | |

| Product dimension range | Suitable bottle range | ml | 3-800 | 3-800 | 5-800 |

| Max. bottle height | mm | ≤180 | ≤200 | ≤200 | |

| Max. Dia. of bottle | mm | ≤80 | ≤80 | ≤80 | |

| Dry cycle | s | 4 | |||

| Hydraulic driving system | Motor power | KW | 11/15 | 18.7/22 | 17 |

| hydraulic pressure | Mpa | 14 | 14 | 14 | |

| Pneumatic system | Min. Air pressure | Mpa | ≥0.8 | 1.0 | 1.0 |

| Discharge rate of compressed air | M3/mm | ≥0.7 | ≥0.8 | ≥0.8 | |

| Cooling system | Water flowage | M3/h | 3 | 3 | 4 |

| Total rated power with mold heating | KW | 21/25 | 34/38 | 45 | |

| Machine information | Dimension | M | 3.1×1.2×2.2 | 3.5×1.4×2.3 | 4×1.28×2.35 |

| machine weight | Ton | 4.0 | 6.0 | 7.5 | |

Application

Saudi Arabia, Colombia, Panama, South Africa ...