The service life of a horizontal injection molding machine is crucial when making a purchase. It affects both operational costs and production efficiency. On average, these machines last between 10 to 30 years, influenced by factors such as quality, usage, and maintenance.

Read More

What if you could produce multiple parts in a single cycle? Ininjection molding, multi-cavity molds make this possible, increasing efficiency and consistency. These molds allow manufacturers to meet higher demand, reduce cycle times, and maintain part quality.

Read More

In injection molding, stability is crucial for producing high-quality parts. The design of the cooling system plays a key role in ensuring uniform mold temperature and minimizing defects.

Read More

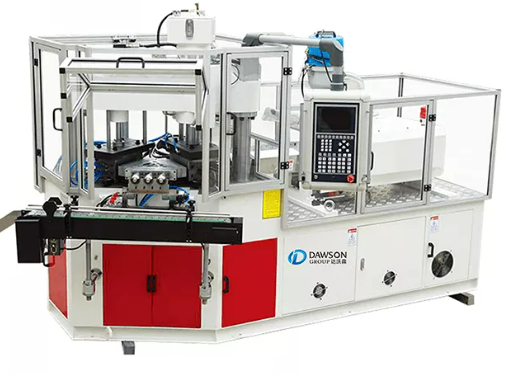

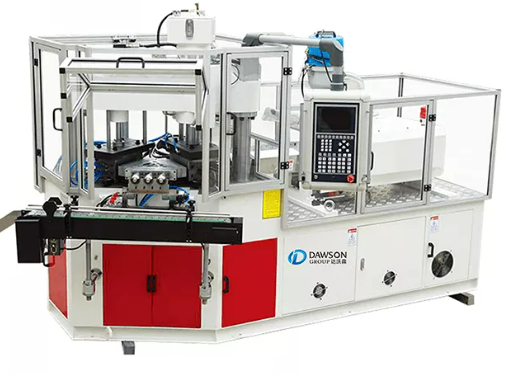

In today's fast-paced manufacturing landscape, efficiency and precision are essential. Horizontal injection molding machines (HIMM) play a crucial role in producing high-quality plastic parts at scale.

Read More

ImpInjection molding is essential for producing complex plastic parts in various industries. The process involves injecting molten material into molds, where it cools and solidifies.

Read More