Views: 0 Author: Site Editor Publish Time: 2025-10-21 Origin: Site

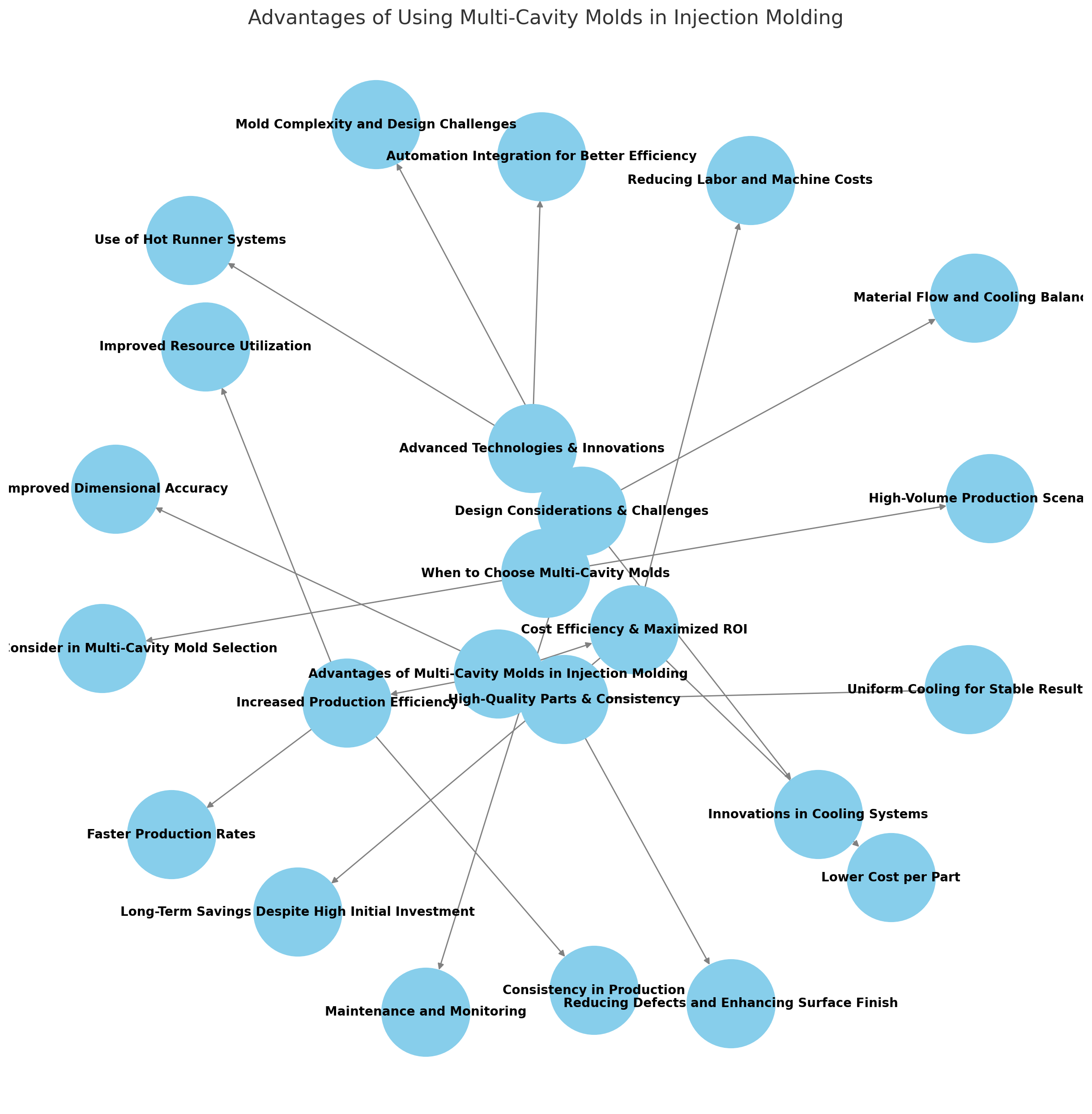

What if you could produce multiple parts in a single cycle? Ininjection molding, multi-cavity molds make this possible, increasing efficiency and consistency. These molds allow manufacturers to meet higher demand, reduce cycle times, and maintain part quality. In this article, we will explore how multi-cavity molds boost production speed, cut costs, and ensure consistent quality in the injection molding process.

Multi-cavity molds are designed to produce several parts simultaneously, significantly reducing production time per part. Compared to single-cavity molds, which can only produce one part per cycle, multi-cavity molds multiply output without increasing cycle times. This increase in production speed is crucial in high-demand industries such as automotive, consumer goods, and medical devices, where rapid delivery is essential.

Faster production means that manufacturers can fulfill orders more quickly, improving time-to-market. The ability to produce multiple parts at once ensures that a high volume of products is created in the same timeframe, boosting overall production efficiency.

By using multi-cavity molds, manufacturers can optimize their resources. Since these molds produce more parts per cycle, less machine time is required for the same output. This also means that labor and other resources are used more efficiently, which ultimately leads to cost savings.

Manufacturers can also maximize the capacity of their injection molding machines, allowing them to produce more parts in less time without needing additional machines or labor. This resource optimization plays a critical role in reducing overhead costs and increasing overall profitability.

Multi-cavity molds ensure consistent and uniform part quality. As each cavity in the mold is designed to produce identical parts, the process helps maintain dimensional accuracy and uniformity across all units. This consistency is essential in industries where even slight variations in parts can lead to performance issues or product defects.

With a well-designed multi-cavity mold, manufacturers can expect high-quality, identical parts produced in each cycle, making it easier to maintain standards and meet customer expectations.

While the upfront cost of multi-cavity molds can be higher due to the complexity and the number of cavities, the long-term cost per part is much lower compared to single-cavity molds. By increasing the number of parts produced per cycle, the cost of labor, material, and machine time is spread across more units, reducing the overall cost per unit.

This cost efficiency is especially important in large-volume production runs, where even small savings per part can add up significantly.

The initial investment required for multi-cavity molds is typically higher than that of single-cavity molds due to the increased complexity. However, the increased production efficiency and reduced cycle times lead to substantial savings over time. These molds help spread the cost of the mold and setup over a greater number of parts, which decreases the cost per unit as production volumes increase.

In high-volume manufacturing, the benefits of multi-cavity molds far outweigh the initial expenses, making them an ideal choice for manufacturers aiming to scale their operations and reduce production costs.

Multi-cavity molds also contribute to cost savings by reducing the need for additional labor and machine time. Since multiple parts are produced in each cycle, the number of cycles needed to meet production targets is greatly reduced. This leads to lower machine utilization and labor costs, as fewer machine setups and changes are required.

The automation of the injection molding process with multi-cavity molds further reduces labor costs by streamlining operations and increasing production speed.

Dimensional accuracy is a key factor in ensuring the quality of molded parts. Multi-cavity molds offer greater consistency by ensuring that every cavity produces an identical part. Proper gate and runner design, along with uniform filling, are crucial in achieving consistent dimensions across all cavities.

Using high-quality injection molding machines equipped with precise control systems further enhances the accuracy of the parts produced.

Multi-cavity molds are instrumental in reducing defects like warping, sink marks, and flash. By ensuring uniform cooling and filling, multi-cavity molds help prevent issues that often arise in high-volume production. The precision in the design of gates and cooling channels ensures that the plastic is distributed evenly, minimizing defects and improving the overall surface finish.

Consistent part quality across all cavities is especially important in industries like automotive and consumer electronics, where defects can significantly affect product performance and customer satisfaction.

Effective cooling is essential for achieving stable, high-quality parts in injection molding. Multi-cavity molds often incorporate advanced cooling systems to ensure that all parts cool at the same rate. This uniform cooling prevents defects such as warping and helps maintain the dimensional stability of each part.

By optimizing the cooling channel design and integrating conformal cooling systems, manufacturers can further improve the cooling efficiency, reducing cycle times and improving the quality of the final product.

Designing multi-cavity molds comes with its challenges, primarily due to the need for precise calculations and considerations for material flow and cooling. Achieving a balanced runner system, ensuring uniform cavity filling, and managing temperature differences require careful planning and expertise.

Manufacturers must also account for the mold’s complexity, which can lead to longer design and setup times. However, the benefits of faster production and cost savings in the long term often outweigh these initial challenges.

Properly managing the material flow and cooling in multi-cavity molds is crucial to achieving consistent quality. Since material flows to multiple cavities simultaneously, the mold design must ensure that the material fills each cavity evenly. The cooling system must also be balanced to ensure uniform solidification, preventing defects like warping and shrinkage.

Advanced simulation tools and mold flow analysis can help optimize these aspects, ensuring that material flow and cooling are well-balanced across all cavities.

Maintaining multi-cavity molds requires careful monitoring to ensure that all cavities continue to function optimally. Regular maintenance is essential to prevent issues such as wear, clogging of cooling channels, or blockages in the runner system. Monitoring the mold during production allows for quick detection of any potential issues, minimizing downtime and ensuring continuous, efficient operation.

Multi-cavity molds are ideal for high-volume production where efficiency and cost reduction are essential. When producing large quantities of identical parts, multi-cavity molds allow manufacturers to meet high demand with reduced cycle times and lower costs per part.

In contrast, single-cavity molds are better suited for low-volume production or when part design is in the testing phase.

When deciding between multi-cavity and single-cavity molds, manufacturers must consider production volume, part complexity, and mold design. Multi-cavity molds are best for high-volume production runs with simple or identical parts, while single-cavity molds may be better for more complex or custom parts.

The choice also depends on budget and time constraints, as multi-cavity molds generally require a larger initial investment and longer lead times.

Hot runner systems are commonly used in multi-cavity molds to improve material flow and reduce waste. By maintaining a consistent melt temperature, hot runners help reduce cycle times and improve the quality of molded parts.

They also allow manufacturers to minimize material waste, which is particularly important when working with expensive or specialty materials.

The integration of robotics and automation into multi-cavity molding systems enhances both speed and precision. Automation can reduce cycle times by handling tasks such as part removal, cooling, and packaging.

Additionally, AI-based systems can monitor the molding process in real time, adjusting parameters as needed to maintain optimal part quality and consistency.

Advancements in cooling technologies are helping to further optimize multi-cavity molds. Conformal cooling, for example, allows for more efficient heat transfer and shorter cycle times, ensuring that parts cool evenly and consistently.

Innovations in cooling systems can also help improve the quality of the final product by preventing defects such as warping, sink marks, and dimensional inaccuracies.

Multi-cavity molds significantly enhance production speed, cost-efficiency, and consistency while maintaining high-quality standards. By producing more parts per cycle, they help reduce cycle times and overall production costs.

To maximize the benefits of multi-cavity molds, manufacturers must focus on mold design, material selection, and process optimization. Partnering with experienced suppliers like Dawson can help optimize production processes and ensure optimal results in high-volume manufacturing.

A: Multi-cavity molds are tools used in injection molding to produce multiple identical parts in a single injection cycle. They improve production efficiency and reduce cycle times.

A: Multi-cavity molds allow multiple parts to be produced simultaneously, reducing cycle times and increasing overall production capacity, making them ideal for high-volume manufacturing.

A: Multi-cavity molds are more cost-effective for large production runs, as they produce multiple parts per cycle, reducing labor and material costs.

A: The injection molding machine ensures that the correct amount of pressure and temperature is applied to all cavities, ensuring uniform part quality and consistent production.

A: Consider production volume, part complexity, material properties, and mold design to ensure optimal performance and cost-efficiency when using multi-cavity molds.