Views: 0 Author: Site Editor Publish Time: 2025-11-21 Origin: Site

A Decade of Trust: How an Ecuadorian Partnership Grew Into a Manufacturing Legacy

For more than a decade, our journey with an Ecuadorian partner has been defined by loyalty, shared ambition, and quiet but powerful transformation. What began with a single blow molding machine has grown into a complete manufacturing ecosystem—over ten Dawson blow molding machines and dozens of molds working steadily in their factory. In Latin America, business is not merely a commercial exchange; it is a relationship rooted in confianza—trust built slowly and strengthened through years of walking side by side.

Over time, we have watched this customer grow from a small-scale producer into a confident, competitive manufacturer. Through market changes, economic ups and downs, and shifting industry demands, the partnership has remained steady. It is the kind of long-term cooperation that becomes rare in today’s fast-paced global market—proof that when two teams share the same values, growth becomes inevitable.

The New Project That Marks a Turning Point

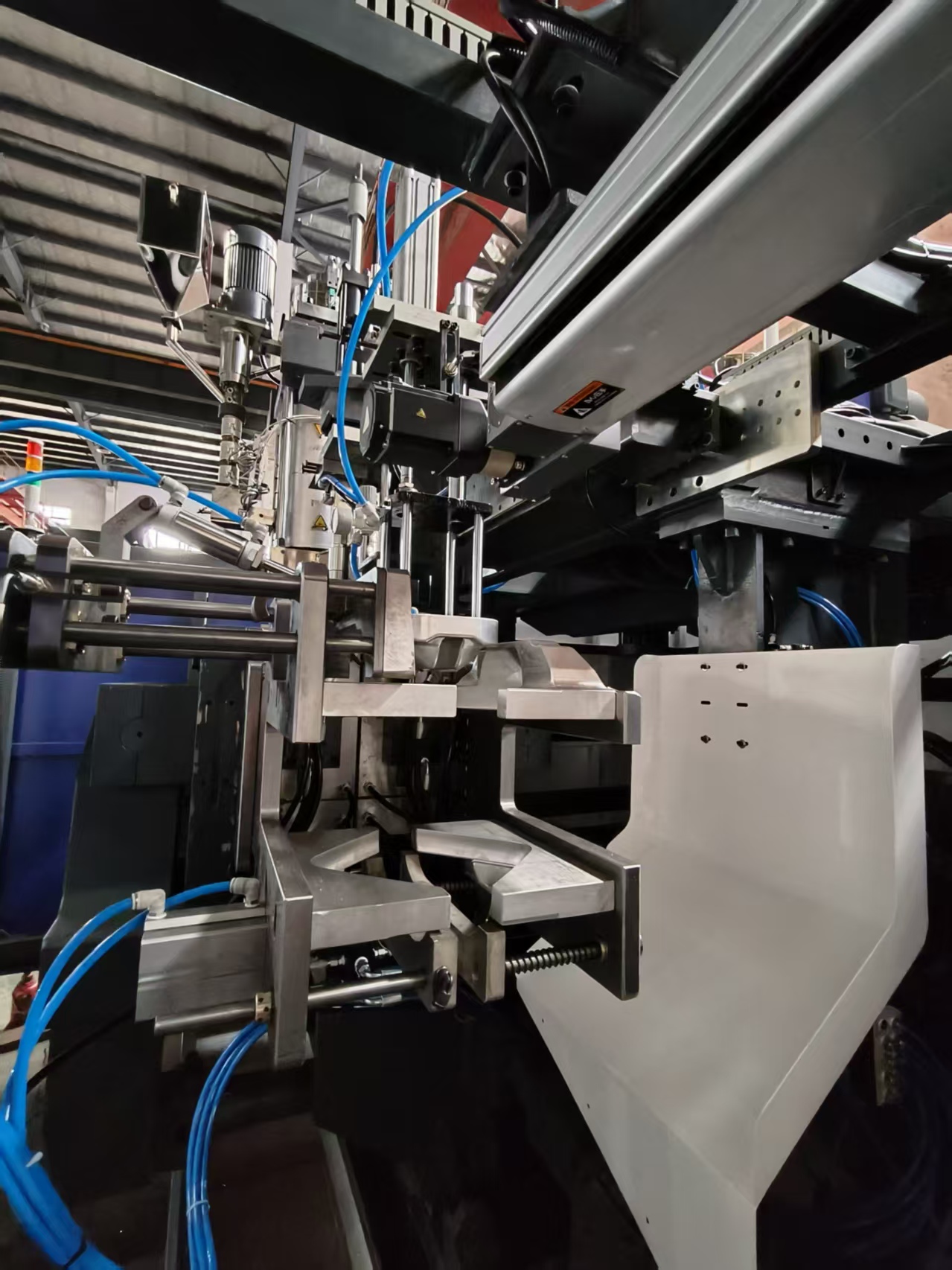

Last month, we shipped a new DSB80-30L single-station blow molding machine tailored for 20L stacking drums, marking a significant milestone in this ongoing relationship. Although this customer already owns multiple Dawson machines, this project carried special meaning—it represented the next step in their industrial upgrade and a deeper commitment to automated, high-efficiency production.

For them, this machine was not “just another purchase.” It symbolized:

① A strategic investment to expand production

②A response to rising market demand for industrial packaging

③ A step toward higher manufacturing stability and quality

④A renewed demonstration of confidence in our technology

Ecuador's manufacturing sector is evolving, driven by growth in agriculture, chemicals, logistics, and export industries. Demand for reliable 20L stacking drums is rising quickly. By adopting this new production line, our partner is positioning themselves not only to satisfy current demand but also to lead upcoming opportunities in their local and regional markets.

Designed With Precision, Delivered With Power

The DSB80-30L machine is more than equipment—it is a carefully engineered solution designed around real industrial needs in Latin America. Built to produce 20L, 1400g stacking drums with consistency and endurance, this configuration focuses on reliability under continuous operation.

Key performance characteristics include:

Ⅰ:55–60 second cycle time

Ⅱ:60+ drums per hour output

Ⅲ:MOOG parison control for superior wall thickness accuracy

Ⅳ:Servo-driven system for stable, energy-efficient operation

Ⅴ:Latest Coutus platen design, ensuring structural rigidity and long-term durability

For experienced manufacturers, these numbers communicate a deeper message: this machine will perform reliably across long shifts, varying temperatures, and demanding production schedules. Ecuador’s industrial environment requires equipment that can maintain consistent quality even under pressure. This line delivers exactly that.

It is a machine built not only to run—but to run well, run long, and run with purpose.

Engineering Solutions for Real Production Challenges

What sets this project apart is that every configuration choice was influenced by real-world experience. Our customer did not guess what they needed; they knew. After operating Dawson machines for many years, they had a clear understanding of which upgrades would improve workflow, reduce downtime, and maintain stable quality.

To match their needs, we integrated:

① A mold designed for clean and reliable flash removal

② A fully automated mechanical arm for product handling

③ A flash conveyor system, improving safety and eliminating manual waste removal

④ A leak tester, guaranteeing that every drum meets rigorous sealing requirements

Each feature reflects a specific production challenge:

① The mechanical arm ensures predictable demolding even during extended production hours.

② The flash conveyor provides a cleaner, safer, and more efficient workshop environment.

③ The leak tester improves quality assurance, reducing returns and reinforcing customer trust.

This is engineering shaped not only by technical standards, but by lived factory experience. It is industrial design that respects the rhythm of work in Latin America.

A Partnership That Goes Beyond Manufacturing

When the machine left our facility at the end of last month, it represented more than a completed order. It was the continuation of a relationship built on understanding, patience, and consistency.

In Latin America, people often say:

“Confianza no se pide; se gana.”

Trust is not asked for; trust is earned.

Through ten years of cooperation, we have earned each other’s trust. We have celebrated growth together, solved problems together, and evolved together. Our machines have become a backbone in their factory, and their stability and success have become a part of our own story.

This is what long-term cooperation looks like—not transactional, but transformational.

Ecuador’s Industrial Market Is Changing—And This Project Arrives at the Perfect Moment

Ecuador is experiencing a shift toward modern manufacturing as industries demand safer, more standardized, and more reliable packaging. Key sectors driving demand for 20L stacking drums include:

Ⅰ: Chemical logistics

Ⅱ:Agricultural products

Ⅲ:Industrial cleaning solutions

Ⅳ:Petrochemical storage

Ⅴ:Export-oriented manufacturing

Factories are increasing automation, buyers are demanding higher quality, and competition with imported containers is intensifying. In such an environment, efficiency and consistency become decisive competitive advantages.

This new 20L drum line equips our partner with:

Ⅰ: Speed to keep up with growing orders

Ⅱ: Stability to minimize downtime

Ⅲ: Product consistency required by major industrial customers

Ⅳ: Production efficiency needed to compete regionally

The timing is perfect.

This machine is entering the Ecuadorian

Looking Toward a Shared Future

As the new production line begins operating in Ecuador, both our teams look toward the future with pride and optimism. Just like the ten machines and dozens of molds that came before it, this new system will become a cornerstone in their expanding capabilities.

For us, this project is not the end of a chapter—it is the beginning of the next one.

Over the next decade, as Ecuador’s industrial packaging sector continues to evolve, we will continue evolving with it. We will support our partner with new designs, faster cycles, cleaner automation, and stronger technical solutions.

The road ahead is full of opportunity.

And we will build it together—one machine, one project, and one decade at a time.