Views: 0 Author: Site Editor Publish Time: 2025-12-05 Origin: Site

A New Chapter in Industrial Power Systems

Since the electrification wave of the Second Industrial Revolution swept across the globe, power systems have been the backbone of industrial transformation. From the roar of steam engines to the widespread adoption of electric motors, every shift in energy fundamentally reshaped production methods and industrial landscapes. Today, in the twenty-first century, a similar revolution is underway. The fierce competition between electric and traditional combustion vehicles in modern China illustrates a broader truth: high-efficiency, low-maintenance, low-emission electric technology is not just transforming transportation—it is redefining industry-wide paradigms of power and efficiency.

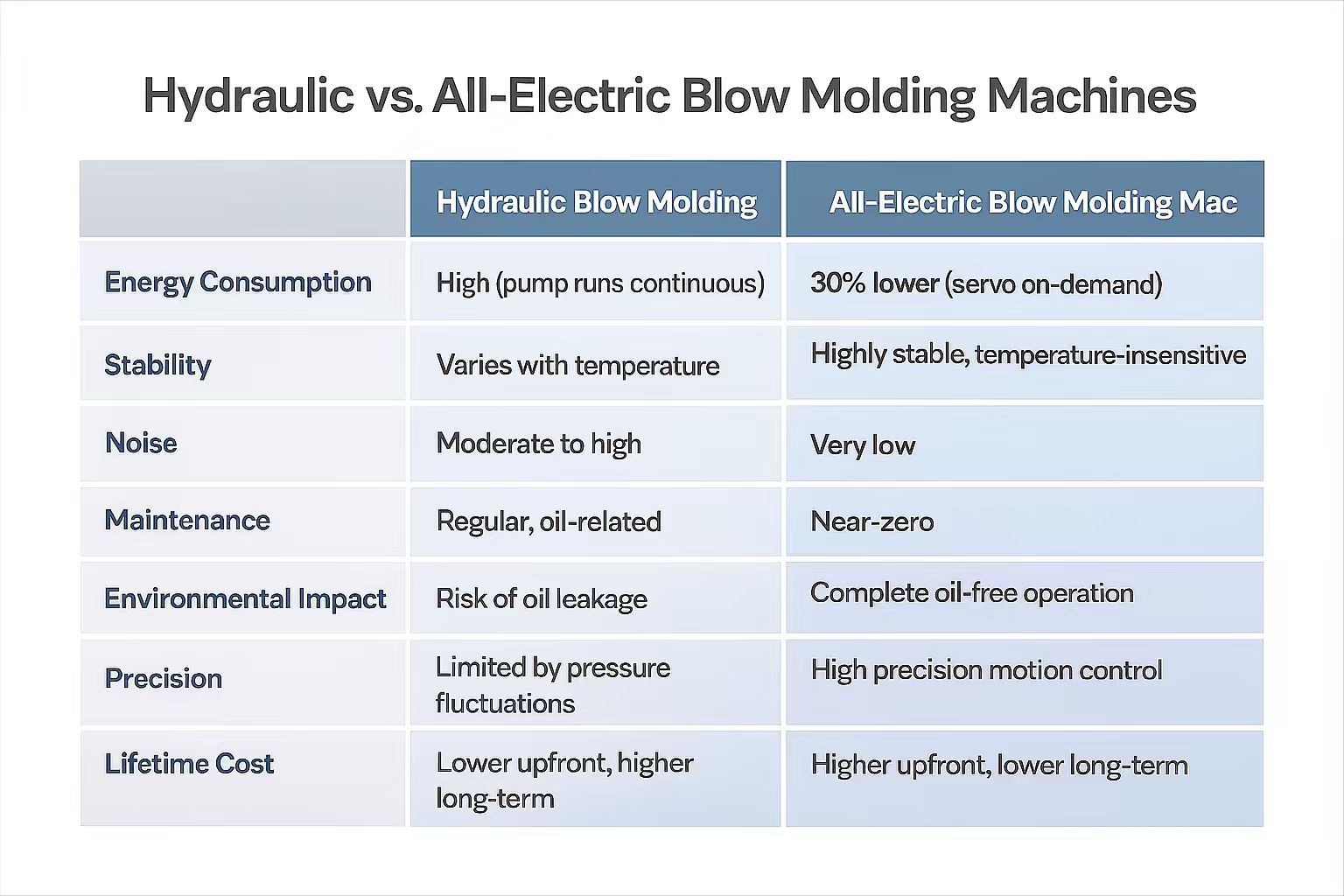

Within manufacturing, quieter but equally profound changes are unfolding. For decades, the blow molding industry has relied on hydraulic drive systems—mature, robust, and aligned with large-scale industrial demands. Yet, as energy efficiency, environmental compliance, and production stability become critical, the inherent limitations of hydraulic systems are increasingly evident. In response, all-electric blow molding machines—driven by fully independent servo systems—are emerging as the next-generation solution. With superior energy efficiency, precise motion control, stability, and oil-free operation, the industry is stepping into its own “electric era,” signaling a decisive turn toward full electrification.

The Hydraulic Blow Molding Machine: Strengths and Structural Limitations

Hydraulic blow molding machines have long been the backbone of global plastic processing. Operating through hydraulic oil pressure, pumps drive fluid to actuate mold closing, parison control, extrusion, and other critical motions. Advantages include high force output, robust construction, and decades of proven engineering.

However, modern production demands expose several limitations:

I. Sensitivity to Temperature

Hydraulic oil is temperature dependent. Rising ambient or operational temperatures reduce viscosity, causing fluctuating pressure, inconsistent cycle times, and reduced dimensional precision. Cold conditions increase viscosity, slowing response and raising energy consumption. Such variations reduce predictability and stability.

II. Noise and Vibration

Continuous operation of hydraulic pumps and valves generates significant mechanical noise, often exceeding modern comfort and safety thresholds. Facilities aiming to improve working conditions or meet stricter environmental standards face substantial challenges.

III. Risk of Leakage

Oil leaks from aging seals, worn hoses, or valves are common. Beyond environmental and safety risks, leaks can halt production—particularly critical in food packaging, cosmetics, and pharmaceuticals.

IV. Higher Long-Term Maintenance

Hydraulic systems require regular care: pumps, valves, seals, filters, and oil need inspection or replacement. Over thousands of hours, maintenance costs and downtime accumulate significantly.

In short, while hydraulic machines exemplify industrial reliability, their constraints are increasingly incompatible with modern efficiency, sustainability, and precision demands.

The All-Electric Blow Molding Machine: A Complete Redefinition of Performance

All-electric blow molding machines adopt a fundamentally different philosophy. Each axis is powered by an independent servo motor, eliminating hydraulic fluid entirely. This architecture offers decisive advantages:

I. Energy Savings of Approximately 30%

Servo motors consume energy only when performing work. Without continuously running pumps, idle energy loss disappears. Across long production cycles, manufacturers report 25–35% energy savings, making the all-electric solution ideal for energy-conscious facilities.

II. Superior Stability and Repeatability

Digital precision replaces fluid-based variability. Temperature fluctuations no longer affect performance, cycle times remain consistent, and product dimensions are more uniform. This predictability is critical for high-end production and industries requiring strict tolerances.

III. High Operational Efficiency

Faster response times, precise acceleration curves, and optimized motion profiles shorten cycle times. Over thousands of daily cycles, these improvements compound into significant productivity gains.

IV. Quiet Operation

Without hydraulic pumps, noise levels drop dramatically. Production becomes quieter, cleaner, and more ergonomic—a key advantage for employee welfare and compliance with noise regulations.

V. Near-Zero Maintenance

Independent, oil-free servo systems eliminate routine maintenance: no pumps, oil changes, filters, or hoses to manage. Long-term maintenance costs approach zero, freeing resources for other operational priorities.

VI. Clean and Environmentally Friendly

Oil-free operation removes contamination risks, essential for food-grade, medical, or premium consumer products. Environmental impact is reduced, and regulatory compliance is simplified.

VII. Long-Term Strategic Value

Though initial investment is higher, all-electric machines deliver lifetime cost savings in energy, maintenance, and product consistency. For manufacturers focused on sustainable competitiveness, they represent a forward-looking choice aligned with global trends.

The Future: Entering the All-Electric Era

Electrification in industry is no fleeting trend; it is a structural shift. Sustainability goals, rising energy costs, and technological innovation accelerate the transition. The blow molding sector faces the same crossroads as other manufacturing industries: remain with familiar hydraulic systems or embrace the all-electric paradigm.

Given their stability, efficiency, environmental benefits, and long-term economic advantages, all-electric blow molding machines are increasingly central to the next industrial era. Forward-thinking manufacturers reexamining operational strategies for reliability and sustainability will find these machines to be not just an upgrade, but the new standard.

Shaping the Future of Blow Molding: The Dawson Group Vision

Every major leap in industrial history has been powered by a redefinition of energy—steam, electricity, automation, and now fully electrified precision systems. The transition from hydraulic to all-electric blow molding machines marks the next chapter in this evolution, reshaping production efficiency, environmental responsibility, and long-term operational stability.

At Dawson Group, we have dedicated over 20 years to the blow molding industry, building a wealth of project experience and technical expertise. We are committed to delivering tailored, reliable solutions that empower manufacturers to embrace the all-electric era with confidence. Our mission extends beyond supplying equipment: we aim to drive sustainable innovation, foster strong partnerships, and help our clients achieve operational excellence across Latin America and beyond.

By combining cutting-edge technology with decades of know-how, Dawson Group envisions a future where energy-efficient, high-precision, and environmentally responsible blow molding is the global standard—a future we are proud to help shape, one machine at a time.