Views: 180 Author: Site Editor Publish Time: 2025-09-16 Origin: Site

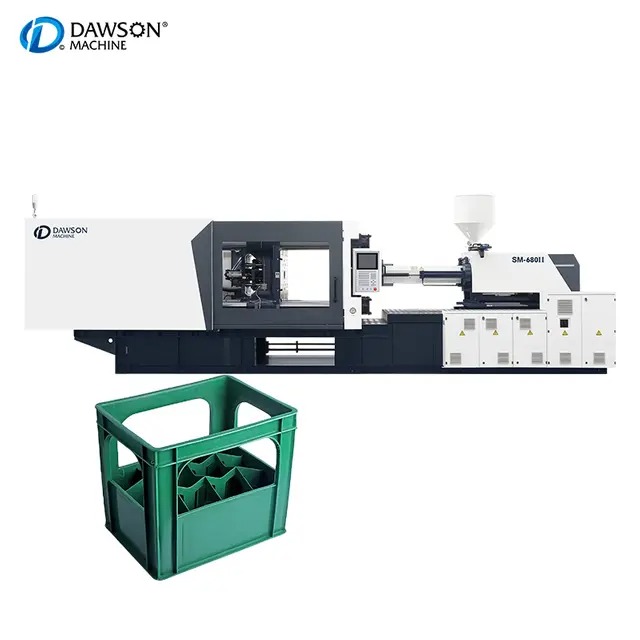

Injection molding machines are the backbone of modern manufacturing, powering industries ranging from automotive to medical devices and consumer electronics. Yet, succeeding in this competitive field requires more than owning the equipment—it demands technical knowledge, process optimization, workforce training, and smart cost management. In this article, we’ll explore the exact steps manufacturers can take to succeed with an injection molding machine, ensuring quality production, consistent output, and long-term profitability.

Every injection molding machine relies on a combination of key components: the injection unit, the clamping system, the mold, and the control system. The injection unit is responsible for melting and injecting plastic into the mold, while the clamping system ensures stability and prevents leakage during the injection cycle. If operators fail to understand how these parts interact, production bottlenecks and quality defects will inevitably arise. Mastering each element’s role is the first step toward long-term success.

The type of resin chosen—whether ABS, polypropylene, nylon, or polycarbonate—directly impacts machine performance. Some materials require higher temperatures or slower cooling times, while others are prone to warping if not carefully managed. Successful operators don’t just load materials; they understand how resin behavior influences the injection molding machine’s efficiency. Matching the right resin with the right processing parameters is critical to avoiding waste and maximizing throughput.

Small errors in setup can have massive consequences. Poor mold alignment, incorrect clamping force, or miscalibrated barrel temperatures often lead to flashing, burn marks, or short shots. Instead of rushing into production, skilled operators dedicate time to fine-tuning the setup phase. Preventing errors at this stage saves both material costs and valuable machine hours, directly improving profitability.

Injection molding success depends heavily on balancing three core variables: temperature, pressure, and cooling. Overheating the resin can cause degradation, while insufficient pressure may lead to incomplete fills. Cooling too quickly may introduce warping or sink marks. Successful operators treat these factors as a three-legged stool: imbalance in one area topples the entire process. Continuous monitoring ensures that every shot meets quality expectations.

Automation tools, such as robotic part removal and real-time sensors, drastically reduce reliance on manual labor. Human error, whether from fatigue or inexperience, is a major source of inconsistency in injection molding. Automating repetitive steps ensures precision, improves safety, and allows skilled workers to focus on higher-level problem-solving rather than routine tasks.

Modern injection molding machines generate enormous amounts of data, from pressure curves to cycle times. By analyzing this data, operators can quickly detect trends that signal potential defects. For example, a sudden increase in injection pressure may indicate nozzle clogging. Data-driven troubleshooting allows manufacturers to address issues before they spiral into costly downtime.

Injection molding benefits greatly from lean manufacturing principles. Reducing waste, optimizing machine layout, and streamlining material flow ensure smoother production. Successful companies implement just-in-time delivery of raw materials and standardized work procedures to minimize inefficiency. These practices not only save costs but also improve delivery times for customers.

One of the leading causes of financial loss in injection molding is unplanned downtime. Preventive maintenance—such as regularly checking hydraulic systems, cleaning filters, and lubricating moving parts—dramatically extends machine life. Manufacturers who prioritize maintenance avoid costly breakdowns and keep production schedules on track.

Cycle time optimization is a balancing act. Shorter cycles increase output but can compromise part quality if cooling is rushed. Successful injection molding operations use simulation tools and real-time monitoring to safely shorten cycle times. This ensures higher profitability while maintaining precise tolerances required by industries like automotive and aerospace.

Even the most advanced injection molding machine cannot compensate for an untrained workforce. Skilled operators know how to adjust settings, detect early signs of defects, and troubleshoot minor issues without halting production. Their expertise directly impacts efficiency, scrap rates, and ultimately profitability.

Formal training programs, often supported by machine manufacturers, provide employees with structured learning. These programs cover machine mechanics, resin science, and process troubleshooting. Successful companies invest in continuous learning opportunities, ensuring employees evolve alongside advancing technology.

Beyond formal training, success requires a workplace culture that encourages innovation and problem-solving. Teams that regularly share knowledge, analyze production data, and propose improvements build a sustainable foundation for success. In injection molding, small incremental improvements often translate to significant cost savings and quality gains.

IoT-enabled injection molding machines allow operators to track temperature, pressure, and cycle time in real-time. Smart sensors detect anomalies early and trigger alerts, preventing defects or machine failures. By leveraging IoT, companies can operate more proactively rather than reactively.

Simulation software allows engineers to test mold designs and processing conditions virtually before committing to physical production. This reduces the risk of costly mold rework and accelerates product development. Companies that adopt simulation tools achieve faster time-to-market and more reliable production outcomes.

Data analytics transforms raw machine data into actionable insights. By analyzing trends, companies can identify inefficiencies, predict maintenance needs, and optimize scheduling. The result is not just better production but smarter business decision-making across the entire organization.

Purchasing an injection molding machine involves more than the upfront cost. Manufacturers must also consider energy usage, maintenance, downtime, and labor. The following table highlights typical cost factors that influence total cost of ownership:

| Cost Factor | Impact on Profitability |

|---|---|

| Machine Purchase Price | Initial investment; affects ROI timeline |

| Energy Consumption | Ongoing operational expense |

| Preventive Maintenance | Reduces breakdowns, extends machine lifespan |

| Downtime Costs | Lost revenue due to halted production |

| Labor and Training | Influences efficiency and scrap rates |

Understanding these costs helps companies avoid financial surprises and plan for long-term profitability.

Energy usage is one of the largest recurring costs in injection molding. Upgrading to energy-efficient machines or adopting hybrid/electric models significantly reduces electricity bills. Lower operating costs directly increase margins without sacrificing quality or speed.

Overemphasis on speed often results in higher defect rates, while prioritizing quality at the expense of volume can slow growth. Successful manufacturers strike a balance by aligning production goals with customer requirements, ensuring profitability without compromising standards.

Scaling requires careful timing. Adding new machines too early can strain cash flow, while waiting too long may result in missed opportunities. Successful companies monitor production capacity and customer demand to decide the right moment for expansion.

Diversifying product lines can boost revenue but risks overloading existing capacity. Smart manufacturers expand strategically, ensuring new product introductions align with available machine capabilities and workforce readiness.

Long-term success extends beyond the factory floor. Building strong relationships with resin suppliers ensures stable pricing and availability, while close collaboration with customers allows for co-development of new products. These partnerships create a stable ecosystem for sustainable growth.

Success in the plastic injection molding machine industry requires more than operational efficiency—it demands mastery of fundamentals, skilled operators, smart technology adoption, and financial discipline. By combining these strategies, manufacturers can achieve consistent quality, reduce costs, and scale operations profitably. Injection molding isn’t just a process; it’s a growth engine for businesses prepared to optimize every aspect of production.

1. What is the most common challenge with an injection molding machine?

The most common challenge is maintaining consistent quality while balancing temperature, pressure, and cooling times.

2. How do I know if my injection molding machine is properly optimized?

If your scrap rates are low, cycle times are consistent, and downtime is minimal, your machine is likely optimized.

3. What materials work best for injection molding machines?

ABS, polypropylene, and nylon are popular choices, though the best material depends on product requirements.

4. How often should an injection molding machine undergo maintenance?

Preventive maintenance should be conducted monthly, with major inspections scheduled annually.

5. Can small manufacturers succeed with injection molding, or is it only for large-scale plants?

Small manufacturers can succeed by focusing on niche products, lean workflows, and leveraging digital tools for efficiency.