- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

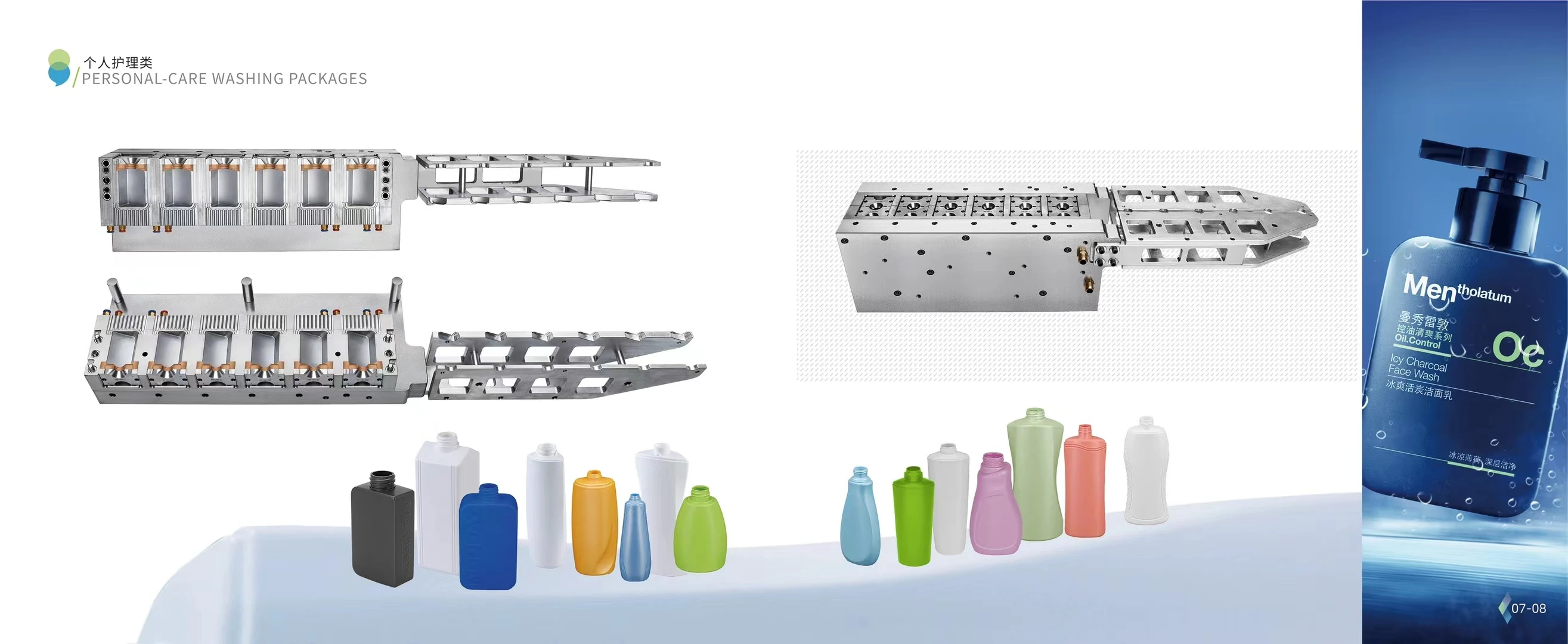

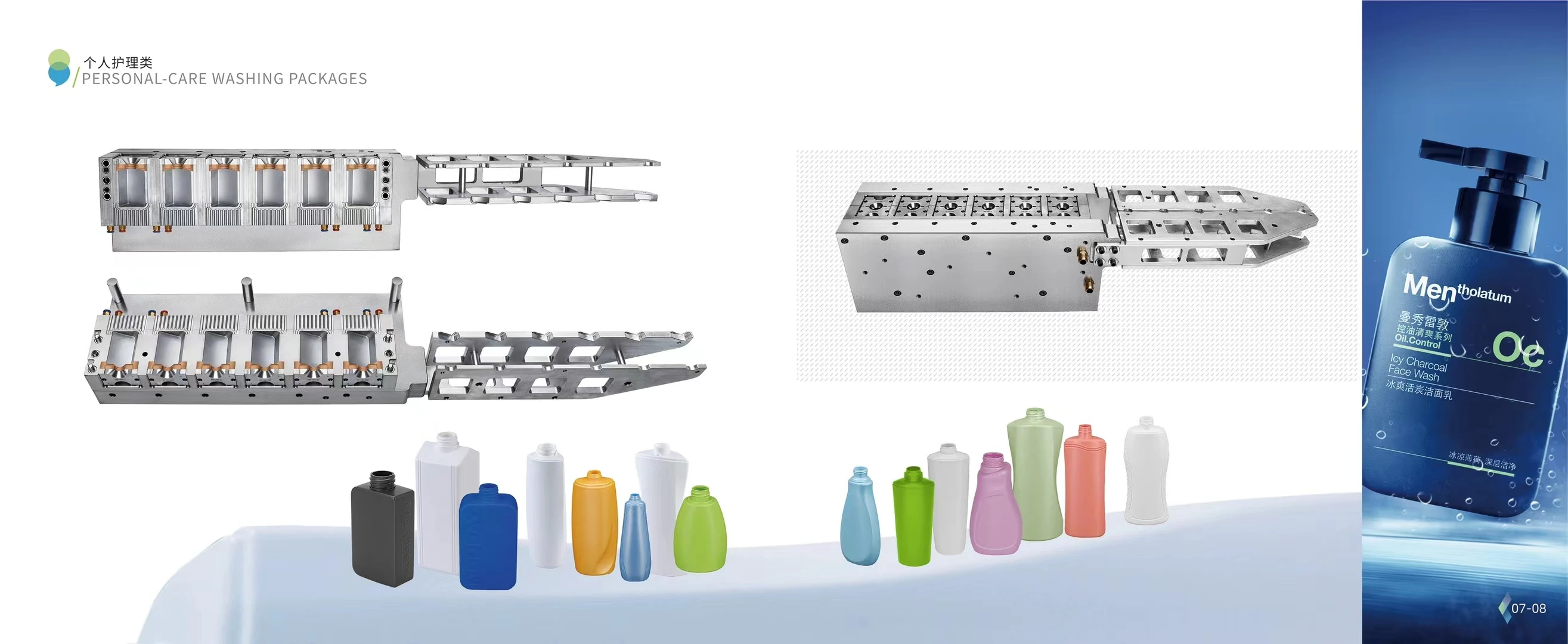

| Mould material: | |

|---|---|

| Auto-deflashing: | |

| Cavity: | |

| Surface treatment: | |

| Mould base: | |

| Equipment: | |

| Logo customized: | |

| Availability: | |

| Quantity: | |

1L

Dawson

8477101090

Extrusion blow molding is a method of manufacturing hollow thermoplastic parts. The well-known blow molding objects include bottles, barrels, cans, boxes, and all containers for packaging food, beverages, cosmetics, drugs, and daily necessities. Large blow molded containers are typically used for packaging chemical products, lubricants, and bulk materials. Other blow molded products include balls, corrugated pipes, and toys. For the automotive manufacturing industry, fuel tanks, car shock absorbers, seat backs, center brackets, and armrest and headrest covers are all blow molded. For the machinery and furniture manufacturing industry, blow molded parts include shells, door frames, frames, pottery jars, or boxes with an open surface.

The most common blow molding extrusion plastic material is high-density polyethylene, and most milk bottles are made of this polymer. Other polyolefins are also commonly processed through blow molding. According to their usage, styrene polymers, polyvinyl chloride, polyester, polyurethane, polycarbonate, and other thermoplastic materials can also be used for blow molding.

Recently, engineering plastics have been widely accepted in the automotive industry. The selection of materials is based on mechanical strength, weather resistance, electrical properties, optical properties, and other properties.

Our Advantage

| 1. Mould cavity & Cutting edges use high quality Stainless steel S136H, which is the best material for blowing moulds. | ||||

| 2. Our necking plate is using imported JAPAN material DC53,Heat treatment to HRC62. | ||||

| 3. Our cooling system is covered very average,all the necking area, handle area had designed perfect cooling system to make sure long time smooth running. | ||||

| 4. Our de-flashing unit and mask material is using High quality Aluminium alloy 6061#. | ||||

| 5. De-flashing cylinder all use high quality Taiwan AIRTAC cylinder. |

Application

Extrusion blow molding is a method of manufacturing hollow thermoplastic parts. The well-known blow molding objects include bottles, barrels, cans, boxes, and all containers for packaging food, beverages, cosmetics, drugs, and daily necessities. Large blow molded containers are typically used for packaging chemical products, lubricants, and bulk materials. Other blow molded products include balls, corrugated pipes, and toys. For the automotive manufacturing industry, fuel tanks, car shock absorbers, seat backs, center brackets, and armrest and headrest covers are all blow molded. For the machinery and furniture manufacturing industry, blow molded parts include shells, door frames, frames, pottery jars, or boxes with an open surface.

The most common blow molding extrusion plastic material is high-density polyethylene, and most milk bottles are made of this polymer. Other polyolefins are also commonly processed through blow molding. According to their usage, styrene polymers, polyvinyl chloride, polyester, polyurethane, polycarbonate, and other thermoplastic materials can also be used for blow molding.

Recently, engineering plastics have been widely accepted in the automotive industry. The selection of materials is based on mechanical strength, weather resistance, electrical properties, optical properties, and other properties.

Our Advantage

| 1. Mould cavity & Cutting edges use high quality Stainless steel S136H, which is the best material for blowing moulds. | ||||

| 2. Our necking plate is using imported JAPAN material DC53,Heat treatment to HRC62. | ||||

| 3. Our cooling system is covered very average,all the necking area, handle area had designed perfect cooling system to make sure long time smooth running. | ||||

| 4. Our de-flashing unit and mask material is using High quality Aluminium alloy 6061#. | ||||

| 5. De-flashing cylinder all use high quality Taiwan AIRTAC cylinder. |

Application