- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Mould material: | |

|---|---|

| Auto-deflashing: | |

| Cavity: | |

| Surface treatment: | |

| Mould base: | |

| Equipment: | |

| Model Number: | |

| Availability: | |

| Quantity: | |

1L

Dawson

8477101090

Three quarters of blow molded products are manufactured by the extrusion blow molding method. The extrusion process forces materials to pass through a hole or mold to manufacture products.

Polymer blending is defined as a process of increasing the grade of a polymer or polymer system through melt mixing. The mixing process ranges from the addition of a single additive to the treatment of multiple additives, polymer alloys, and reactive mixing. Blended polymers are usually granulated for further processing. However, industry is increasingly interested in combining blending with the next steps, such as extrusion of profiles, to avoid reheating the polymer.

People use various types of melt mixing equipment, from roller mills and batch mixers to single screw and twin screw extrusion machines. Continuous mixing and dispensing (extrusion machine) is the most commonly used equipment because it can provide consistent quality plastic blow molding processing products and reduce operating costs. There are two types of mixing: distributed mixtures can be evenly distributed in the mixing process without the need for high shear stress. This type of mixture is called extensional mixing or laminar mixing.

Our Advantage

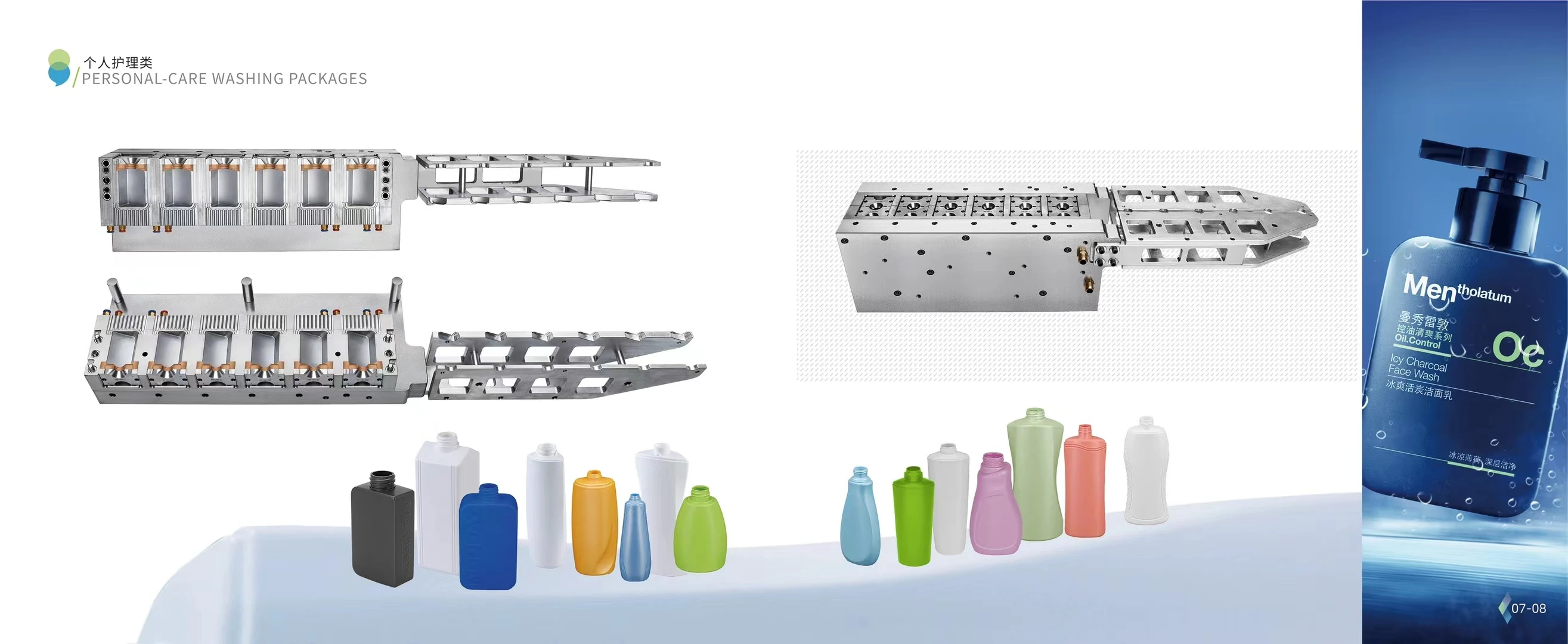

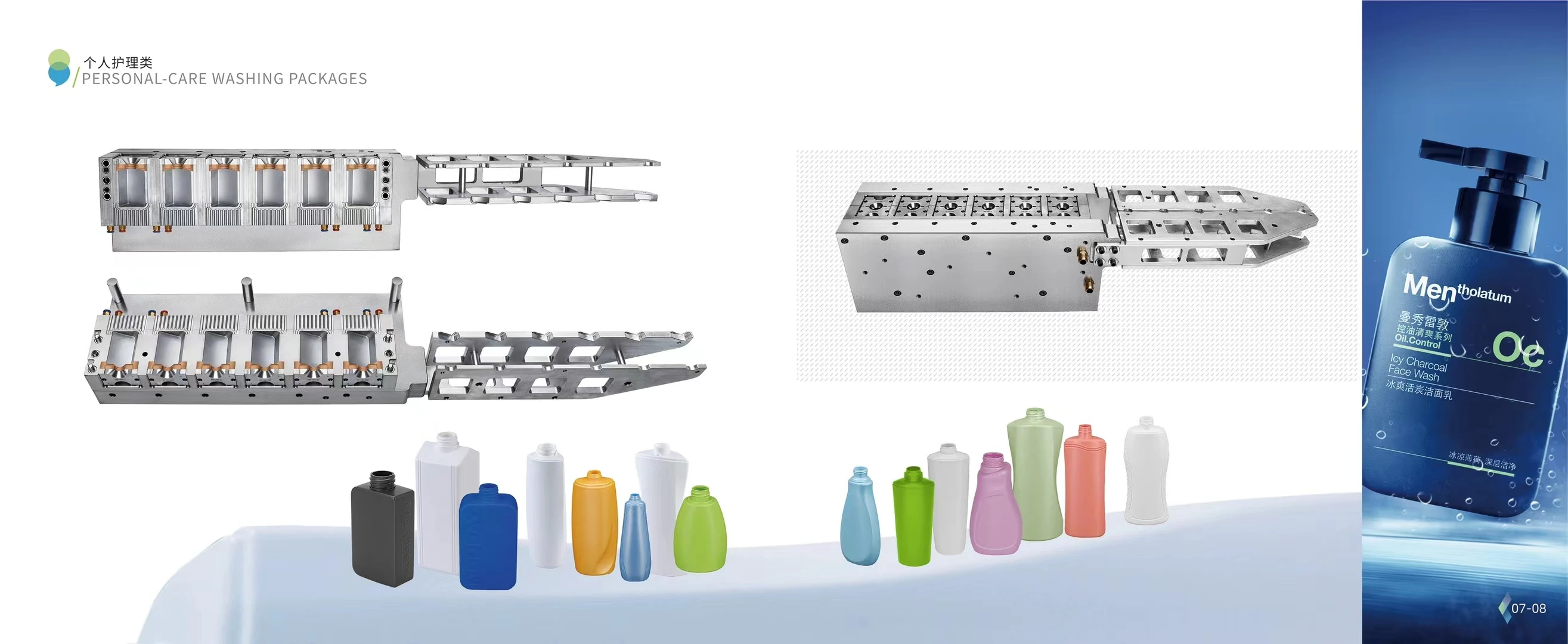

| 1. Mould cavity & Cutting edges use high quality Stainless steel S136H, which is the best material for blowing moulds. | ||||

| 2. Our necking plate is using imported JAPAN material DC53,Heat treatment to HRC62. | ||||

| 3. Our cooling system is covered very average,all the necking area, handle area had designed perfect cooling system to make sure long time smooth running. | ||||

| 4. Our de-flashing unit and mask material is using High quality Aluminium alloy 6061#. | ||||

| 5. De-flashing cylinder all use high quality Taiwan AIRTAC cylinder. |

Application

Three quarters of blow molded products are manufactured by the extrusion blow molding method. The extrusion process forces materials to pass through a hole or mold to manufacture products.

Polymer blending is defined as a process of increasing the grade of a polymer or polymer system through melt mixing. The mixing process ranges from the addition of a single additive to the treatment of multiple additives, polymer alloys, and reactive mixing. Blended polymers are usually granulated for further processing. However, industry is increasingly interested in combining blending with the next steps, such as extrusion of profiles, to avoid reheating the polymer.

People use various types of melt mixing equipment, from roller mills and batch mixers to single screw and twin screw extrusion machines. Continuous mixing and dispensing (extrusion machine) is the most commonly used equipment because it can provide consistent quality plastic blow molding processing products and reduce operating costs. There are two types of mixing: distributed mixtures can be evenly distributed in the mixing process without the need for high shear stress. This type of mixture is called extensional mixing or laminar mixing.

Our Advantage

| 1. Mould cavity & Cutting edges use high quality Stainless steel S136H, which is the best material for blowing moulds. | ||||

| 2. Our necking plate is using imported JAPAN material DC53,Heat treatment to HRC62. | ||||

| 3. Our cooling system is covered very average,all the necking area, handle area had designed perfect cooling system to make sure long time smooth running. | ||||

| 4. Our de-flashing unit and mask material is using High quality Aluminium alloy 6061#. | ||||

| 5. De-flashing cylinder all use high quality Taiwan AIRTAC cylinder. |

Application