- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

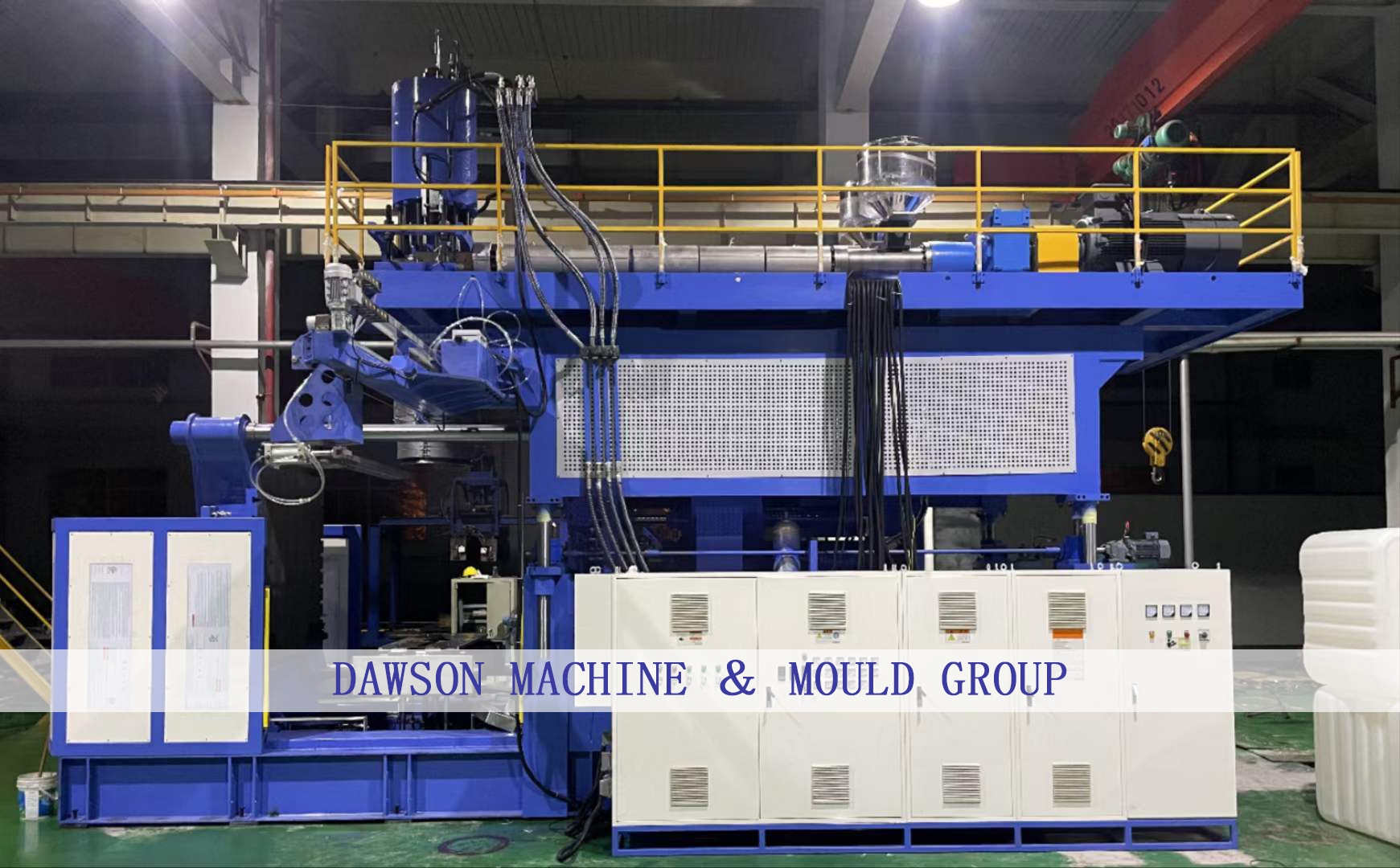

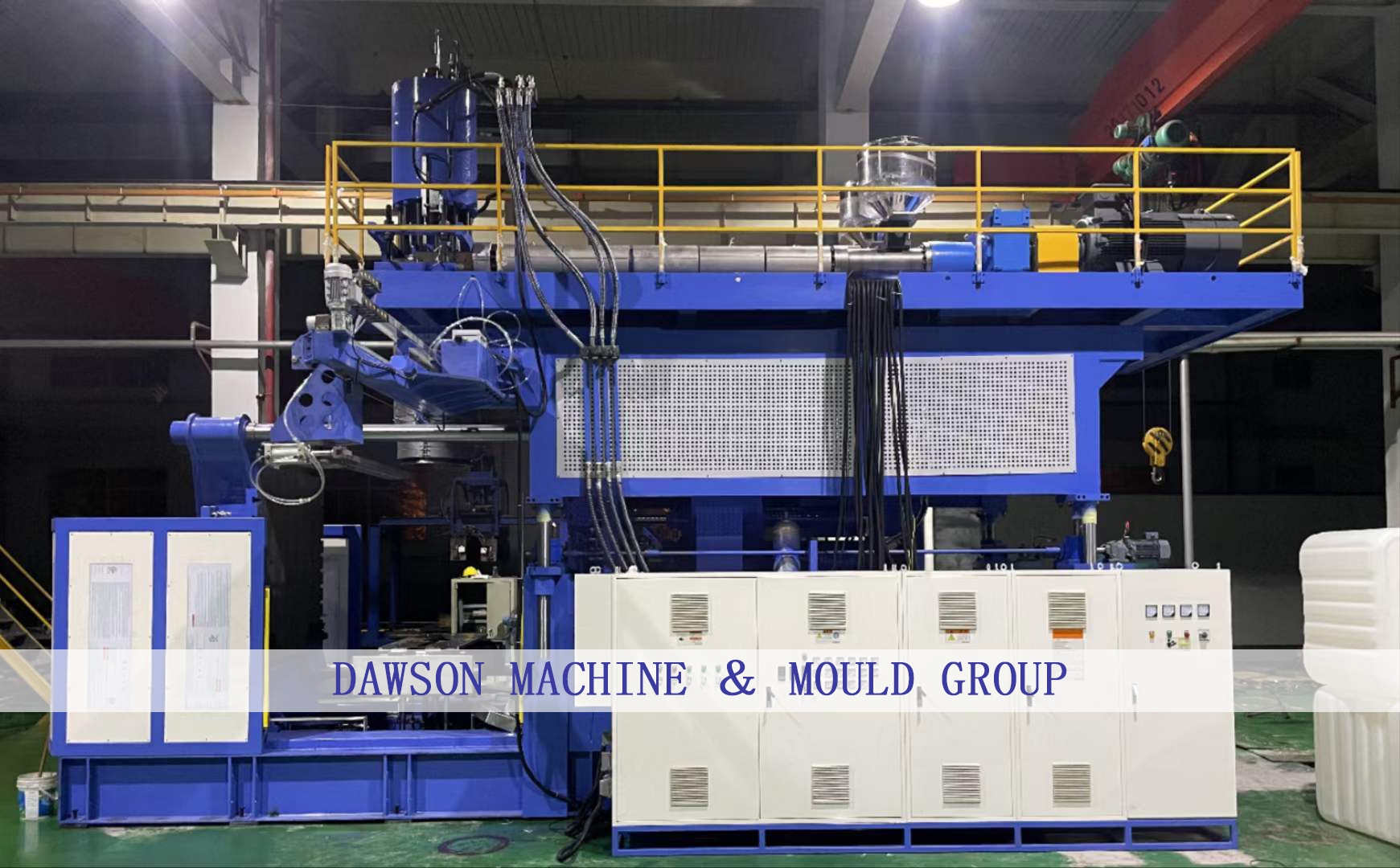

DAWSON

Here are some additional details about the IBC tank blow molding machine:

Multi-layer capabilities: Some advanced IBC tank blow molding machines offer multi-layer capabilities. This means they can produce tanks with multiple layers, each layer having different properties. For example, the inner layer can be made of food-grade material, while the outer layer can provide additional strength and UV resistance.

Industry compliance: The IBC tank blow molding machine complies with industry standards and regulations, such as safety guidelines and quality certifications. Manufacturers often invest in machines that meet international standards to ensure their products meet the required quality and safety standards

Technological advancements: The field of blow molding continues to evolve, and new technological advancements are being incorporated into IBC tank blow molding machines. These advancements include faster cycle times, improved energy efficiency, enhanced automation, and advanced control systems for greater precision and reliability.

Here are some additional details about the IBC tank blow molding machine:

Multi-layer capabilities: Some advanced IBC tank blow molding machines offer multi-layer capabilities. This means they can produce tanks with multiple layers, each layer having different properties. For example, the inner layer can be made of food-grade material, while the outer layer can provide additional strength and UV resistance.

Industry compliance: The IBC tank blow molding machine complies with industry standards and regulations, such as safety guidelines and quality certifications. Manufacturers often invest in machines that meet international standards to ensure their products meet the required quality and safety standards

Technological advancements: The field of blow molding continues to evolve, and new technological advancements are being incorporated into IBC tank blow molding machines. These advancements include faster cycle times, improved energy efficiency, enhanced automation, and advanced control systems for greater precision and reliability.