- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

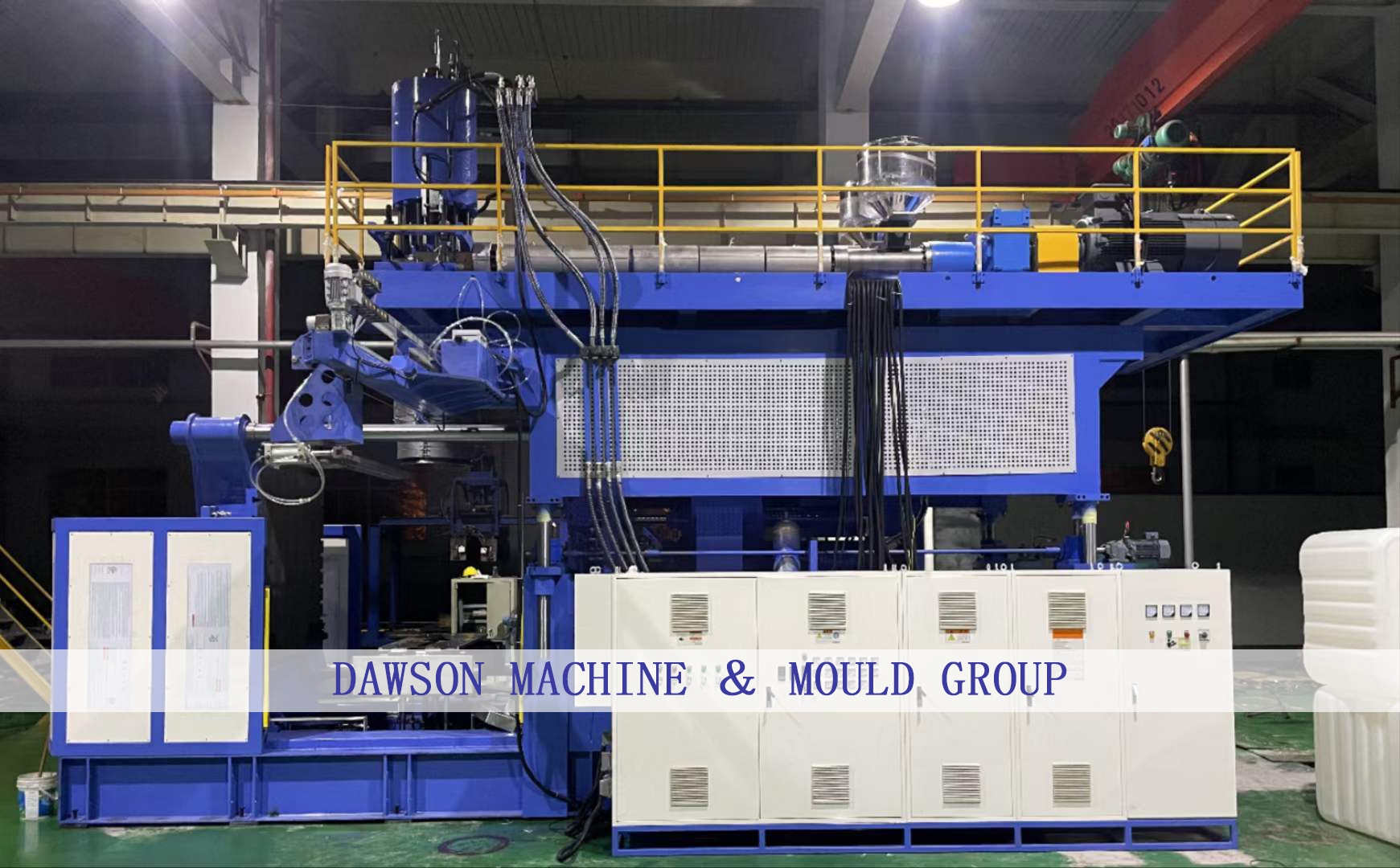

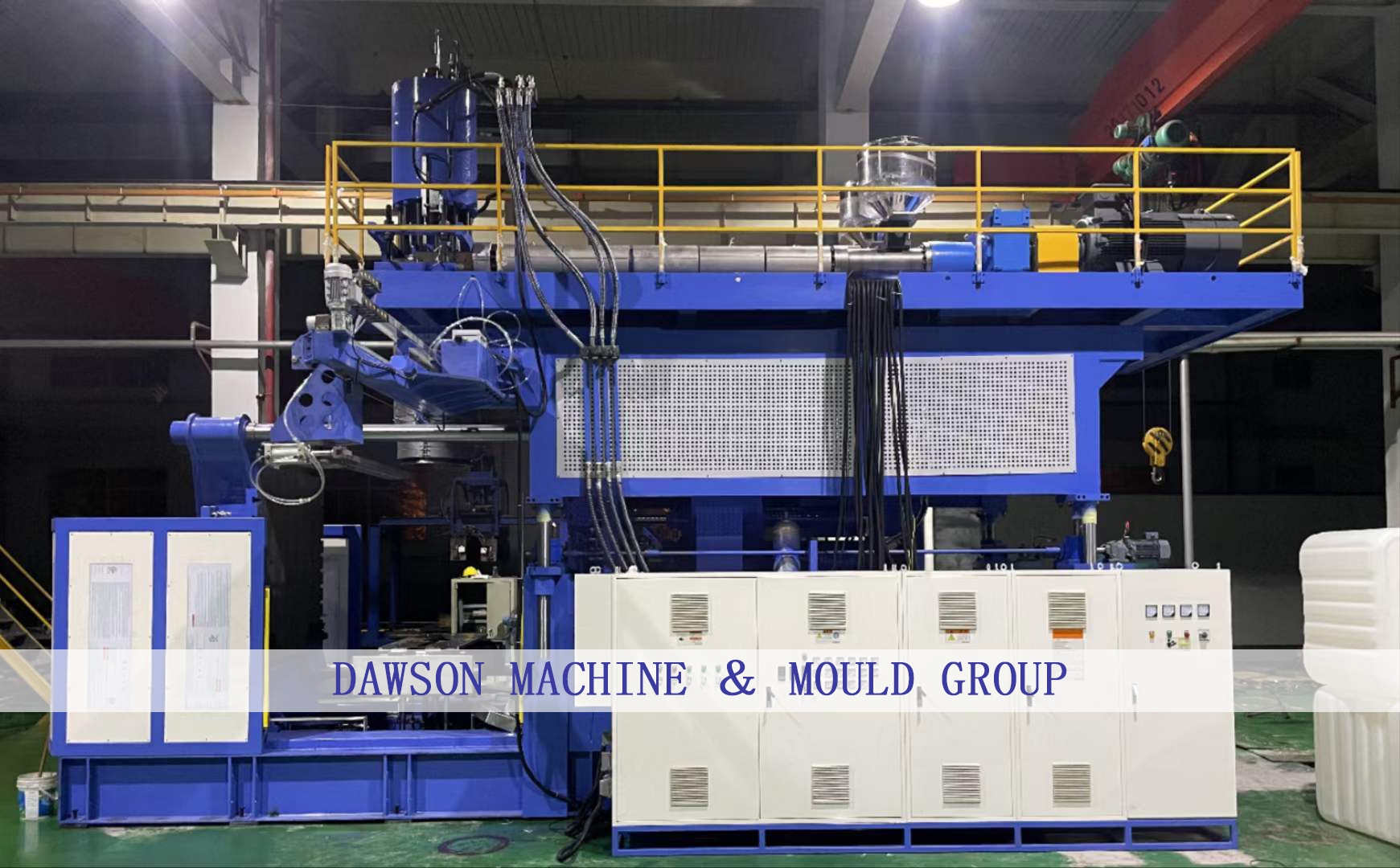

DAWSON

Here are some additional details about the IBC tank blow molding machine:

Material selection: The machine is compatible with a wide range of plastic materials, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), and polypropylene (PP). This allows manufacturers to choose the material that best suits their specific application requirements.

Automation features: The machine is equipped with automation features that enhance productivity and reduce manual labor. These features include automatic mold change systems, robotic handling systems for seamless part ejection, and integrated quality control systems for efficient inspection and defect detection.

Maintenance and servicing: The machine is engineered for easy maintenance and servicing. It is equipped with user-friendly interfaces and diagnostic systems that allow operators to monitor and troubleshoot any issues quickly. Regular maintenance ensures the machine operates at its optimal performance level and extends its lifespan.

Here are some additional details about the IBC tank blow molding machine:

Material selection: The machine is compatible with a wide range of plastic materials, including high-density polyethylene (HDPE), low-density polyethylene (LDPE), and polypropylene (PP). This allows manufacturers to choose the material that best suits their specific application requirements.

Automation features: The machine is equipped with automation features that enhance productivity and reduce manual labor. These features include automatic mold change systems, robotic handling systems for seamless part ejection, and integrated quality control systems for efficient inspection and defect detection.

Maintenance and servicing: The machine is engineered for easy maintenance and servicing. It is equipped with user-friendly interfaces and diagnostic systems that allow operators to monitor and troubleshoot any issues quickly. Regular maintenance ensures the machine operates at its optimal performance level and extends its lifespan.